Petrosan Stainless Steel Repair Clamp

PetroSan Oilfield Engineering co. is one of the high quality steel band repair clamp manufacturer and suppliers like Single Band SS304/316L repair clamp, SS304/316L Double band repair clamp, SS304/316L triple band repair clamps.

Single Band Stainless Steel Clamp with Ductile Iron Lugs, Manufacturer Double Band Stainless Steel Clamp with Ductile Iron Lugs, Manufacturer Special Range Double Band Stainless Steel Clamp with Ductile Iron Lugs, Manufacturer Triple Band Stainless Steel Clamp with Ductile Iron Lugs, Manufacturer Single Band Stainless Steel Repair Clamps with Drop-In Bolts, Manufacturer Double Band Stainless Steel Repair Clamps with Drop-In Bolts, Manufacturer Triple Band Stainless Steel Repair Clamps with Drop-In Bolts.

In the plant of petrosan, We Manufacturer and suppliers of High pressure SS 304 / 316l Band Stainless Steel Clamp, Manufacturer and suppliers of Single Band Stainless Steel Clamp with Ductile Iron Lugs, Manufacturer and suppliers Double Band Stainless Steel Clamp with Ductile Iron Lugs, Manufacturer and suppliers Special Range Double Band Stainless Steel Clamp with Ductile Iron Lugs, Manufacturer of Triple Band Stainless Steel Clamps.

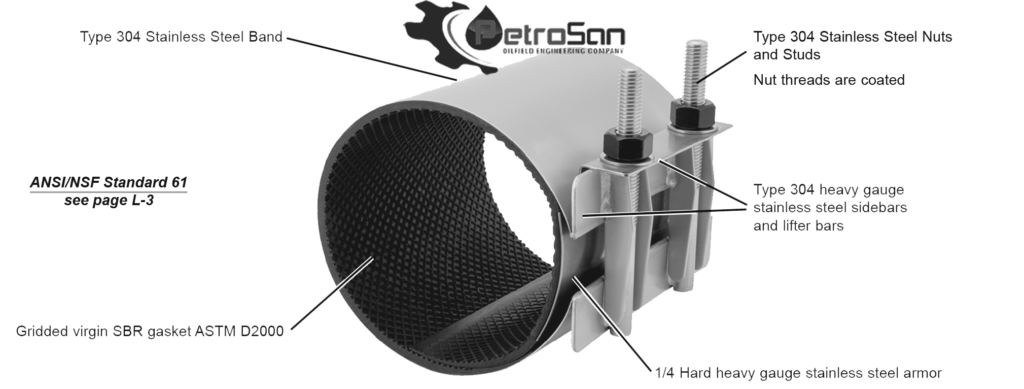

Specifications:

Band: Type 304 stainless steel.

Studs and Heavy Type 304 stainless steel per ASTM A193 and A194 Coated nut threads to prevent galling Studs are.

Hex Nuts: permanently attached to the clamp sidebar by means of a Metal Inert Gas (MIG) weld.

Lugs: Type 304 heavy gauge stainless steel, MIG welded to clamp sidebar Lugs are rounded and tapered for easy installation Sidebars: Type 304 heavy gauge stainless steel Tungsten Inert Gas (TIG) welded to form a strong, permanent fusion with the repair clamp band.

Lifter Bar: Type 304 heavy gauge stainless steel Lip curve holds bolts in position while tightening and serves as a bearing surface for stainless steel nuts and washers.

Gasket: Gridded virgin Styrene Butadiene Rubber (SBR) compounded for water service per ASTM D2000 Gasket ends are tapered for a dependable seal SBR is suitable for temperatures of 150°F continuous, 180°F intermittent.

Armor: 1/4 hard heavy gauge stainless steel vulcanized and recessed into the gasket to ensure uniform compression against the pipe.

Passivated: All clamps are fully passivated by means of a chemical technique which restores the corrosion resistant characteristics of the stainless steel Options • Conductivity strips.

Include: • NBR (Buna-N) gasket (suitable for natural gas applications) Recommended for 220°F continuous and/or

240°F intermittent

• EPDM gasket recommended for 300°F continuous and/or 320°F intermittent

• 316 stainless steel

• 1″ offset gasket for overlapping clamps for extended lengths.

Belleville Washers use on HDPE: for Belleville washers, also referred to as spring washers, promote consistant force on the gasket as the pipe diameter expands and contracts The Belleville washers are made of 17-7 PH stainless steel Depending on the pipe size and recommended installation torque, Belleville washers are used singularly, or in a stack to allow for more expansion/contraction of the pipe Flat washers not always included or needed on some HDPE products

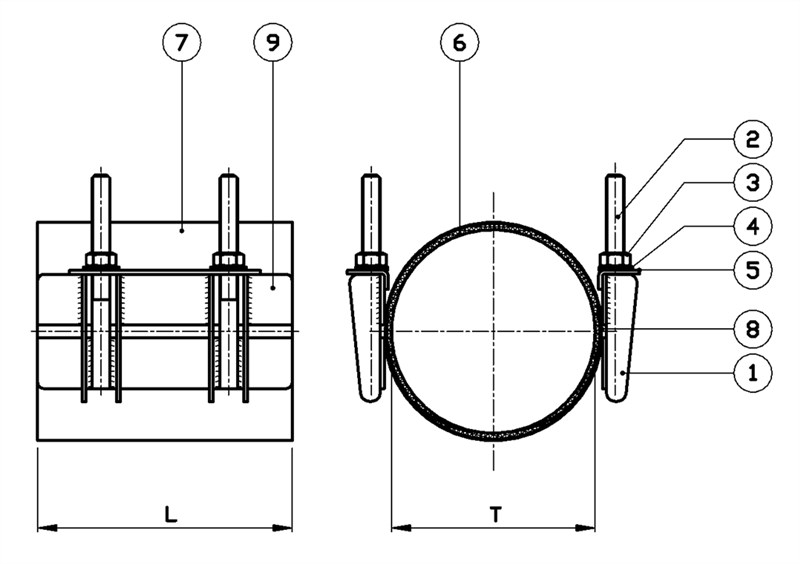

Material Component :

| 1. | Finger | Stainless steel 304L |

| 2. | Stud | Stainless steel 304L |

| 3. | Nut | Stainless steel A4 anti friction |

| 4. | Washer | Stainless steel A4 |

| 5. | Bridge | Stainless steel 304L |

| 6. | Lining | EPDM rubber |

| 7. | Body plate | Stainless steel 304L |

| 8. | Spanner plate vulcanized | Stainless steel 304L |

| 9. | Side plate | Stainless steel 304L |

Types of Petrosan stainless steel repair clamp :

- Single Band Stainless Steel Clamp with Ductile Iron Lugs

- Double Band Stainless Steel Clamp with Ductile Iron Lugs

- Special Range Double Band Stainless Steel Clamp with Ductile Iron Lugs

- Triple Band Stainless Steel Clamp with Ductile Iron Lugs

- Single Band Stainless Steel Repair Clamps with Drop-In Bolts

- Double Band Stainless Steel Repair Clamps with Drop-In Bolts

- Triple Band Stainless Steel Repair Clamps with Drop-In Bolts

- Single Band Stainless Steel Clamp with Ductile Iron Lugs for HDPE Pipe

- Double Band Stainless Steel Clamp with Ductile Iron Lugs for HDPE Pipe

- Triple Band Stainless Steel Clamp with Ductile Iron Lugs for HDPE Pipe

- Single Band All Stainless Steel Clamp

- Double Band All Stainless Steel Clamp

- Triple Band All Stainless Steel Clamp

- Wrap Clamp with Finger Lugs

- Single Band All Stainless Steel Clamp for HDPE Pipe

- Double Band All Stainless Steel Clamp for HDPE Pipe

- Triple Band All Stainless Steel Clamp for HDPE Pipe

- Abandoned Corp Cap

- Snap or Wrap Clamp

- All Stainless Steel Snap or Wrap Clamp

- Repair Clamp for Coupling Solvent Weld PVC

- Bell Joint Leak Clamp

- Fabricated Bell Joint Leak Clamp

- Repair Clamp for Integral Bell Solvent Weld PVC

Advantages of Petrosan Repair Clamps :

- PetroSan Clamp made out of a pre-rolled plate of stainless steel 304L

- PetroSan Clamp is manufactured with a hinge point in order to simplify installation

- Design with welded stainless steel 304L studs and fingers

- PetroSan Clamp is completely pickled and passivated after welding

- Stainless steel nuts: A4 quality with anti-friction through yellow passivation to prevent galling

- Gasket of EPDM rubber with waffle structure and rounded tops

- Vulcanized spanner plate

- Tolerance of double band repair clamp is max. 24 mm (depends on diameter pipe)

- PetroSan Clamp available in different diameters: DN 80 up to DN 600

- PetroSan Clamp available in different lenghts: 200, 250, 300, 400, 500 and 600 mm (other lengths on request)

- Indication pressure class for (waste)water: 16 bar for DN 80 up to DN 150, 10 bar for DN 175 up to DN 450 and 6 bar from DN 500

PetroSan Clamp Reference number and dimensions:

| PetroSan ref. no. | T mm | L12 mm | Bolts (no x M x L) | Theoretical weight/kg |

|---|---|---|---|---|

| PetroSan 001-25001 | 88 – 110 | 150 | 4XM14X180 | 3.0 |

| PetroSan 001-25002 | 88 – 110 | 200 | 4XM14X180 | 3.6 |

| PetroSan 001-25003 | 88 – 110 | 250 | 6XM14X180 | 4.9 |

| PetroSan 001-25004 | 88 – 110 | 300 | 6XM14X180 | 5.4 |

| PetroSan 001-25005 | 88 – 110 | 400 | 8XM14X180 | 7.2 |

| PetroSan 001-25006 | 100 – 120 | 600 | 12XM14X180 | 12 |

| PetroSan 001-25007 | 105 – 125 | 250 | 6XM14X180 | 5.2 |

| PetroSan 001-25007 | 105 – 125 | 300 | 6XM14X180 | 5.8 |

| PetroSan 001-25009 | 105 – 125 | 400 | 8XM14X180 | 7.7 |

| PetroSan 001-250010 | 108 – 128 | 200 | 4XM14X180 | 3.8 |

| PetroSan 001-250011 | 108 – 128 | 250 | 6XM14X180 | 5.2 |

| PetroSan 001-250012 | 108 – 128 | 300 | 6XM14X180 | 5.8 |

| PetroSan 001-250013 | 108 – 128 | 400 | 8XM14X180 | 7.7 |

| PetroSan 001-250014 | 108 – 128 | 500 | 10XM14X180 | 9.7 |

| PetroSan 001-250015 | 114 – 136 | 300 | 6XM14X180 | 5.8 |

| PetroSan 001-250016 | 130 – 150 | 250 | 6XM14X180 | 5.3 |

| PetroSan 001-250017 | 130 – 150 | 300 | 6XM14X180 | 5.8 |

| PetroSan 001-250018 | 135 – 155 | 300 | 6XM14X180 | 5.9 |

| PetroSan 001-250019 | 140 – 160 | 250 | 6XM14X180 | 5.4 |

| PetroSan 001-250020 | 140 – 160 | 300 | 6XM14X180 | 6.0 |

| PetroSan 001-250021 | 140 – 160 | 400 | 8XM14X180 | 7.9 |

| PetroSan 001-250022 | 140 – 160 | 500 | 10XM14X180 | 10.0 |

| PetroSan 001-250023 | 150 – 170 | 200 | 4XM14X180 | 3.9 |

| PetroSan 001-250024 | 159 – 180 | 200 | 4XM14X180 | 4.1 |

| PetroSan 001-250025 | 159 – 180 | 250 | 6XM14X180 | 5.5 |

| PetroSan 001-250026 | 159 – 180 | 300 | 6XM14X180 | 6.2 |

| PetroSan 001-250027 | 159 – 180 | 400 | 8XM14X180 | 8.2 |

| PetroSan 001-250028 | 159 – 180 | 500 | 10XM14X180 | 10 |

| PetroSan 001-250029 | 159 – 180 | 600 | 12XM14X180 | 12 |

| PetroSan 001-250030 | 165 – 186 | 300 | 6XM14X180 | 6.2 |

| PetroSan 001-250031 | 165 – 186 | 500 | 10XM14X180 | 10 |

| PetroSan 001-250032 | 176 – 196 | 300 | 6XM14X180 | 6.3 |

| PetroSan 001-250033 | 190 – 210 | 200 | 4XM14X180 | 4.3 |

| PetroSan 001-250034 | 190 – 210 | 300 | 6XM14X180 | 6.5 |

| PetroSan 001-250035 | 210 – 230 | 200 | 4XM14X180 | 4.4 |

| PetroSan 001-250036 | 210 – 230 | 300 | 6XM14X180 | 6.7 |

| PetroSan 001-250037 | 210 – 230 | 400 | 8XM14X180 | 8.8 |

| PetroSan 001-250038 | 210 – 230 | 600 | 12XM14X180 | 13 |

| PetroSan 001-250039 | 215 – 238 | 200 | 4XM14X180 | 4.4 |

| PetroSan 001-250040 | 215 – 238 | 300 | 6XM14X180 | 6.7 |

| PetroSan 001-250041 | 215 – 238 | 400 | 8XM14X180 | 8.9 |

| PetroSan 001-250042 | 215 – 238 | 500 | 10XM14X180 | 11 |

| PetroSan 001-250043 | 225 – 246 | 300 | 6XM14X180 | 6.9 |

| PetroSan 001-250044 | 225 – 246 | 400 | 8XM14X180 | 9.1 |

| PetroSan 001-250045 | 230 – 250 | 400 | 8XM14X180 | 9.1 |

| PetroSan 001-250046 | 240 – 260 | 200 | 4XM14X180 | 4.7 |

| PetroSan 001-250047 | 240 – 260 | 300 | 6XM14X180 | 7.0 |

| PetroSan 001-250048 | 240 – 260 | 400 | 8XM14X180 | 9.3 |

| PetroSan 001-250049 | 250 – 270 | 300 | 6XM14X180 | 7.1 |

| PetroSan 001-250050 | 263 – 285 | 300 | 6XM14X180 | 7.3 |

| PetroSan 001-250051 | 263 – 285 | 400 | 8XM14X180 | 9.6 |

| PetroSan 001-250052 | 263 – 285 | 500 | 10XM14X180 | 12 |

| PetroSan 001-250053 | 269 – 289 | 200 | 4XM14X180 | 4.8 |

| PetroSan 001-250054 | 269 – 289 | 300 | 6XM14X180 | 7.3 |

| PetroSan 001-250055 | 269 – 289 | 400 | 8XM14X180 | 9.7 |

| PetroSan 001-250056 | 273 – 293 | 300 | 6XM16X180 | 8.2 |

| PetroSan 001-250057 | 273 – 293 | 400 | 8XM16X180 | 11 |

| PetroSan 001-250058 | 282 – 302 | 200 | 4XM16X180 | 5.5 |

| PetroSan 001-250059 | 282 – 302 | 400 | 8XM16X180 | 11 |

| PetroSan 001-250060 | 295 – 315 | 300 | 6XM16X180 | 8.4 |

| PetroSan 001-250061 | 295 – 315 | 500 | 10XM16X180 | 14 |

| PetroSan 001-250062 | 315 – 335 | 300 | 6XM16X180 | 8.7 |

| PetroSan 001-250063 | 315 – 335 | 400 | 8XM16X180 | 12 |

| PetroSan 001-250064 | 315 – 335 | 500 | 10XM16X180 | 14 |

| PetroSan 001-250065 | 322 – 344 | 300 | 6XM16X180 | 8.8 |

| PetroSan 001-25005 | 322 – 344 | 400 | 8XM16X180 | 12 |

| PetroSan 001-250066 | 322 – 344 | 500 | 10XM16X180 | 15 |

| PetroSan 001-250067 | 337 – 361 | 300 | 6XM16X180 | 8.9 |

| PetroSan 001-250068 | 337 – 361 | 500 | 10XM16X180 | 15 |

| PetroSan 001-250069 | 347 – 370 | 400 | 8XM16X180 | 12 |

| PetroSan 001-250070 | 347 – 370 | 500 | 10XM16X180 | 15 |

| PetroSan 001-250071 | 347 – 370 | 600 | 12XM16X180 | 19 |

| PetroSan 001-250072 | 365 – 385 | 300 | 6XM16X180 | 9.3 |

| PetroSan 001-250073 | 365 – 385 | 400 | 8XM16X180 | 12 |

| PetroSan 001-250074 | 365 – 385 | 500 | 10XM16X180 | 16 |

| PetroSan 001-250075 | 390 – 410 | 400 | 8XM16X180 | 13 |

| PetroSan 001-250076 | 396 – 420 | 250 | 6XM16X180 | 8.5 |

| PetroSan 001-250077 | 396 – 420 | 300 | 6XM16X180 | 9.6 |

| PetroSan 001-250078 | 396 – 420 | 400 | 8XM16X180 | 13 |

| PetroSan 001-250079 | 396 – 420 | 500 | 10XM16X180 | 16 |

| PetroSan 001-250080 | 410 – 430 | 250 | 6XM16X180 | 8.6 |

| PetroSan 001-250081 | 410 – 430 | 400 | 8XM16X180 | 13 |

| PetroSan 001-250082 | 420 – 440 | 300 | 6XM16X180 | 12 |

| PetroSan 001-250083 | 420 – 440 | 400 | 8XM16X180 | 16 |

| PetroSan 001-250084 | 420 – 440 | 500 | 10XM16X180 | 20 |

| PetroSan 001-250085 | 420 – 440 | 600 | 12XM16X180 | 24 |

| PetroSan 001-250086 | 440 – 465 | 500 | 10XM16X180 | 23 |

| PetroSan 001-250087 | 450 – 470 | 500 | 10XM16X180 | 23 |

| PetroSan 001-250088 | 490 – 510 | 600 | 12XM16X180 | 28 |

| PetroSan 001-250089 | 505 – 530 | 300 | 6XM16X180 | 14 |

| PetroSan 001-250090 | 505 – 530 | 400 | 8XM16X180 | 19 |

| PetroSan 001-250091 | 505 – 530 | 500 | 10XM16X180 | 24 |

| PetroSan 001-250092 | 505 – 530 | 600 | 12XM16X180 | 29 |

| PetroSan 001-250093 | 520 – 540 | 400 | 8XM16X180 | 19 |

| PetroSan 001-250094 | 520 – 540 | 500 | 10XM16X180 | 24 |

| PetroSan 001-250095 | 520 – 540 | 600 | 12XM16X180 | 29 |

| PetroSan 001-250096 | 525 – 550 | 300 | 6XM16X180 | 15 |

| PetroSan 001-250097 | 540 – 565 | 500 | 10XM16X180 | 25 |

| PetroSan 001-250098 | 590 – 610 | 600 | 12XM16X180 | 31 |

| PetroSan 001-250099 | 605 – 630 | 600 | 12XM16X180 | 31 |

Clamp Test & Material Approvals :

- Tested by PETROSAN according to BS8561

- WRAS / W270 approved rubber

- Product approved acc. to KIWA BRL-K777 (PN10, DN40 – DN 400)

We Manufacture, Export and supply to many Countries as follows :

- ASIA – India, Japan, Thailand, Singapore, Sri lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary,Belarus, Bulgaria, Slovakia, Moldova

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See

- South America – Argentina, Chile, Brazil, Colombia, Paraguay

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger,Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara

- Southern Africa – South Africa, Namibia, Botswana,Lesotho, Swaziland

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda,Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles.