PIPE REPAIR CLAMPS IN UNITED KINGDOM - UK

PetroSan Engineering Co., Ltd. We provide top-notch piping clamp because we are a prestigious firm with an ISO certification and we have nearly 10 years of industry experience in pipe clamp. We manufacture a variety of pipe leak repair clamp in United Kingdom-UK.

In United Kingdom-UK, PetroSan oilfield Engineering Co., With a global industrial presence and a major fabricator, manufacturer and world wide supplier of Pipe leak repair clamp, Leak repair clamps, Pipe Clamp, Steel pipe leak repair clamp, Heavy duty pipe leak repair clamp, Steel pipe leak repair split clamp, high pressure pipe repair clamps, Split Repair Clamp, Split Sleeve Repair Clamp, Split Pipe Repair Clamp, Split Sleeve Leak Repair Clamp, Split Sleeve Pipe Repair Clamp, Split Sleeve Pipeline Repair Clamps, Split Sleeve Clamp, Split Pipe Clamp, Split Collar Clamp, Split Barrel Repair Clamp, Split Bolt Ground Clamps in United Kingdom-UK.

Pipe Leak Repair Clamp / Sleeves :

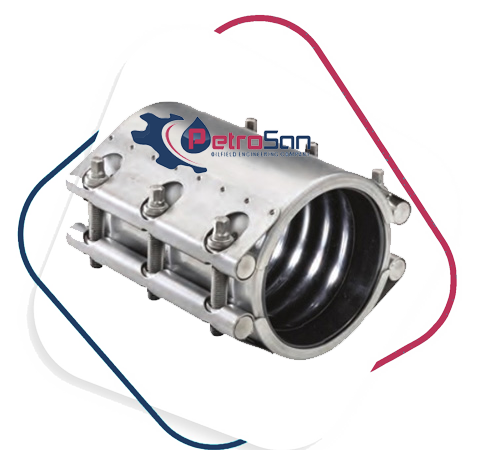

A pipe repair clamp is a device used to fix broken or leaking pipelines. It is a circular or sleeve-like device that wraps around the pipe to cover the damaged area and is normally secured with bolts or other fasteners.

A mechanical tool called a “pipe repair clamp” can be used to seal a leaky section of a pipeline without having to completely replace or shut it down. This pipeline repair sleeve is made to fit over a section of leaky pipeline and offer a temporary or long-term seal to stop leaks. In order to accommodate different pipeline diameters, pressures, and types of damage, pipeline repair clamps come in a variety of sizes and designs in India.

Stainless steel, carbon steel, or ductile iron are common high-strength materials used in their construction, and seals are used to provide a tight fit and prevent leaks. In sectors including chemical processing, water supply, and oil and gas, pipeline repair clamps are a common emergency repair and maintenance solution In United Kingdom-UK.

What is a Pipe Clamps?

Pipe Repair Clamp working pressure chart :

| Class Temp. F |

#150 | #300 | #400 | #600 | #900 | #1500 | #2500 |

| -20 TO 200 | 258 | 740 | 990 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 675 | 900 | 1350 | 2025 | 3375 | 5625 |

| 300 | 230 | 655 | 875 | 1315 | 1970 | 3280 | 5470 |

| 400 | 200 | 635 | 845 | 1270 | 1900 | 3170 | 5280 |

| 500 | 270 | 600 | 800 | 1200 | 1795 | 2995 | 4990 |

| 600 | 140 | 550 | 730 | 1095 | 1640 | 2735 | 4560 |

| 650 | 125 | 535 | 715 | 1075 | 1610 | 2685 | 4475 |

| 700 | 110 | 535 | 710 | 1065 | 1600 | 2665 | 4440 |

| 750 | 95 | 505 | 670 | 1010 | 1510 | 2520 | 4200 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2060 | 3430 |

| 850 | 65 | 270 | 355 | 535 | 805 | 1340 | 2230 |

| 900 | 50 | 170 | 230 | 345 | 515 | 860 | 1430 |

| 950 | 35 | 105 | 140 | 205 | 310 | 515 | 860 |

| 1000 | 20 | 50 | 70 | 105 | 155 | 260 | 430 |

| Test pressure = 1.5 x (working pressure based on class and temperature) Environment conditions -20 to 100 degrees F |

|||||||

A pipe repair clamp works by:

2. Tightening the clamp: To put pressure on the pipe, the clamp is tightened, usually with bolts or screws.

3. Sealing the leak: A watertight seal is created by the clamp’s pressure, which seals the leak or damage.

4. Strengthening the pipe: The clamp gives the pipe more support and strength, which helps to stop additional deterioration or cracking.

– Stop the leak – Prevent additional corrosion in the pipe

– Lower the pipe’s pressure

The clamp is a dependable and efficient method of repairing pipes because it evenly presses on the pipe to contain leaks and stop additional damage.

Pipe repair clamp material grade specification :

The materials used to make pipe repair split clamps usually offer strength, durability, and resistance to wear and corrosion. The following are typical material requirements for split clamps used in pipe repair:

1. Body Material:

– Ductile Iron (ASTM A536)

– Carbon Steel (ASTM A105)

– Stainless Steel (ASTM A182 F304 or F316)

2. Bolts and Nuts:

– Stainless Steel (ASTM A193 B8M or B8T)

– Carbon Steel (ASTM A193 B7 or B16)

3. Gasket Material:

– Neoprene (ASTM D2000)

– EPDM (ASTM D2000)

– Viton (ASTM D2000)

4. Coatings:

– Zinc Plating (ASTM B633)

– Chrome Plating (ASTM B657)

– Powder Coating (ASTM D7803)

5. Other Specifications:

– ASME B16.5 for dimensions and tolerances.

– ASME B31.3 for pipe fabrication and installation.

These material requirements guarantee that the split clamps will be able to endure a range of environmental factors while still offering the mended pipe a trustworthy seal. However, the manufacturer, industry, and application may all have an impact on the precise material parameters. It is imperative that, for the particular pipe repair split clamp application, one refers to the manufacturer’s recommendations as well as industry requirements.

Pipeline Repair Clamp Types.

There are several types of pipeline repair clamps, each designed for specific applications and pipe types. Some common types include:

1. Standard Repair Clamps: General-purpose clamps for everyday repairs.

2. Wide Range Clamps: Adjustable clamps for various pipe sizes.

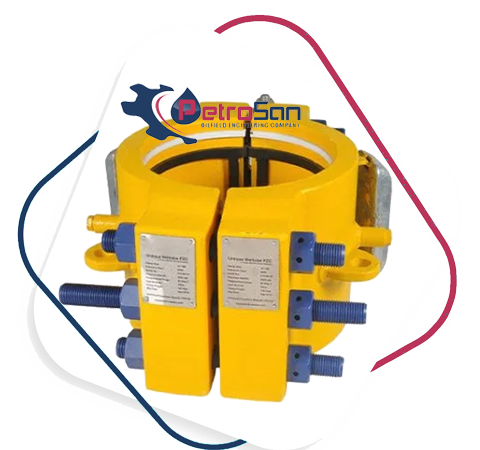

3. High-Pressure Clamps: Designed for high-pressure pipelines.

4. Low-Pressure Clamps: For lower-pressure applications.

5. Corrosion-Resistant Clamps: Made with materials like stainless steel or titanium for corrosive environments.

6. Weldable Clamps: Can be welded in place for permanent repairs.

7. Bolt-On Clamps: Attached with bolts for easy installation.

8. Split Clamps: Can be installed without removing the pipe.

9. Wrap-Around Clamps: Wrap around the pipe without needing to be slid over the end.

10. Emergency Repair Clamps: Temporary clamps for quick fixes.

11. Permanent Repair Clamps: Designed for long-term repairs.

12. Specialty Clamps: For specific pipe materials, like PVC or copper.

Pipe Repair Self-Sealing Clamps | Repair Split Sleeve | High Pressure Bolted Clamp | Pipe External Alignment Clamp | Pipe Repair Block Clamp | Band Strap Clamp

These types of pipeline repair clamps cater to various industries, including:

– Oil and gas

– Water and wastewater

– Chemical processing

– Power generation

– Industrial manufacturing

Each type is designed to meet specific requirements, ensuring effective and reliable pipe repairs.

What Benefits Come With Selecting PetroSan For Your Needs in Pipeline Repair Clamps?

EXPERIENCE : We guarantee that you receive trustworthy and tried-and-true solutions because we have extensive expertise providing pipeline repair services to a variety of industries, including oil and gas and chemical processing.

SWIFT RESPONSE : In order to save downtime and repair costs, PetroSan offers quick response and turnaround times for pipeline repair clamp orders.

PROTECTION : With PetroSan pipeline repair clamps, you can be sure that your pipes are secure and safe with a trustworthy and safe repair alternative.

Manufacturer, Fabricator and suppliers of diffrent types of pipe clamps in United Kingdom-UK.

Manufacturer of Pipe leak repair clamp, Manufacturer of Leak repair clamps, Manufacturer of Pipe Clamp, Manufacturer of Steel pipe leak repair clamp, Manufacturer of Heavy duty pipe leak repair clamp, Manufacturer of Steel pipe leak repair split clamp, Manufacturer of high pressure pipe repair clamps, Manufacturer of Split Repair Clamp, Manufacturer of Split Sleeve Repair Clamp, Manufacturer of Split Pipe Repair Clamp, Manufacturer of Split Sleeve Leak Repair Clamp, Manufacturer of split Sleeve Pipe Repair Clamp, Manufacturer of Split Sleeve Pipeline Repair Clamps, Manufacturer of Split Sleeve Clamp, Manufacturer of Split Pipe Clamp, Manufacturer of Split Collar Clamp, Manufacturer of Split Barrel Repair Clamp, Manufacturer of Split Bolt Ground Clamp in United Kingdom-UK.

In United Kingdom-UK, Petrosan is one stope firm of manufacturing Sealing system coupling, manufacturer of Double Lock Pipe Clamp, manufacturer of Stainless Steel Repair Clamps, manufacturer of Metal-Grip SS Pipe Repair Clamp, manufacturer of Repair Clamp Hinge, manufacturer of Multi flex Coupling, manufacturer of Grip Ring Coupling, manufacturer of GRIP-RING PIPE COUPLING, manufacturer of Sell Pipe Coupling Joints, manufacturer of REPAIR CLAMP DOUBLE JOINT, manufacturer of Bell Joint Repair Clamps, manufacturer of Pipe repair clamp double lug, manufacturer of Stainless Steel Double Pipe Support Clamp, manufacturer of Drain Pipe Repair Clamp, manufacturer of Dismantling Joint And Flange Adaptor, manufacturer of Exhaust Pipe Clamp, manufacturer of Repair Clamps Double Band, manufacturer of Repair Clamp with DI Double Lugs, manufacturer of Pipeline Repair Fittings & Couplings, manufacturer of Double ball rubber expansion joint, manufacturer of Dismantling Joints, manufacturer of Self restrained dismantling joint large stroke type steel, manufacturer of Full Circle Repair Clamp Double Band, manufacturer of Split Sleeve Repair Clamp, manufacturer of Heavy Duty Split Sleeve Repair Clamp , manufacturer of Split Sleeve Repair Clamps, manufacturer of Split Sleeve Repair Clamp and Split Repair Clamps, manufacturer of High Pressure Split Sleeve Repair Clamp, manufacturer of Pin Hole Leak Repair Clamps, manufacturer of Pipe tapping saddle in United Kingdom-UK.

We Manufacture, Export and supply to many Countries as follows :

- United Kingdom-UK – India, Japan, Thailand, Singapore, Sri lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary,Belarus, Bulgaria, Slovakia, Moldova

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See

- South America – Argentina, Chile, Brazil, Colombia, Paraguay

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger,Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara

- Southern Africa – South Africa, Namibia, Botswana,Lesotho, Swaziland

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda,Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles.